Time for more Kit Chat…

Although soft shackles are becoming more popular due to their increased safety and lighter weight, hard shackles are still found in nearly every recovery bag. I have a bunch myself. I even keep a couple permanently attached to my front bumper should the need arise to use them, and since I do a lot of recoveries, the need arises a lot.

Now before you suggest that I just use soft shackles, the recovery brackets on my bumper where the shackles attach, has 90-degree edges, so it won’t take much load for that edge to cut through my soft shackles, thus creating a huge safety issue. This is an extremely obvious failure point (without much load) so it’s metal ones for me (at this attachment point anyway).

The most common size of metal shackles for most 4×4 applications is the 3/4″ 4.75T ones, and although it has a rated Working Load Limit (WLL) of 4.75T (9500lbs), it’s breaking strength is well over 56,000lbs (many have a breaking strength of 68,125lbs). The WLL of 9500lbs is really just for over-head use scenarios, so for 4×4 recoveries, we can push those numbers a bit before we consider doubling up with additional recovery points using a bridle or sling, or even a second winch.

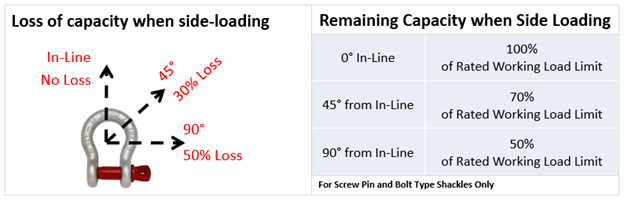

There is a lot of debate about how to use these shackles safely, and one of the big debates is the practice of side loading a hard shackle, and whether or not it is safe. Without argument or debate is that hard shackles provide their greatest strength when pulled straight on (in-line), and the manufacturers will say “Do Not Side Load”, but they also say that if you need to side load a hard shackle, to use the following chart:

Crosby:

I’ve done a LOT of recoveries in my day, and it’s not too often that I’ve been able to pull directly in-line on a hard shackle. More often than not, there has been some amount of side loading. Based on the chart above, side loading a shackle by 90-degrees will result in a strength reduction of 50% in load limits. It drops to 4750lbs WLL, or 28,000 Breaking Strength. Now that’s assuming the shackle can only handle 56,000 but most Rated 3/4″ shackles can handle over 68,000lbs. So you probably shouldn’t be too concerned. There are several other points in your rigging that are more likely to fail first. What’s your winch rated for? What about your winch line?

With that in mind, if you are doing a recovery involving a heavily side loaded shackle, you should probably consider doubling up on the recovery points by setting up complex rigging (double or triple line, a Spanish Burton, or four line pull), and using a bridle or sliding sling to dissipate the loads. The other factor that is often overlooked are the actual recovery points on the bumpers. Those are also designed to be pulled straight on. When those recovery points are side loaded, the welds are far more likely to fail than the hard shackles. This point is rarely discussed but side loading the bumper bracket should be a far bigger concern than side loading the shackle. This is a matter of absolute fact, and anything said to the contrary is uninformed opinion.

Another common debate, which really shouldn’t be at all, is whether we should unscrew the pin by 1/4 turn, or to snug it down. This is a hot topic online, and among recovery gurus like us. The two sides of the argument are that if you snug down the pin, it will be nearly impossible to undo it after it’s subjected to a heavy load, so it’s better to unscrew it a 1/4 turn (but no more). The other argument is that even unscrewing it by as little as 1/4 turn will weaken the strength of the shackle. In short…both are true. They are facts. But unscrewing the pin by 1/4 turn will only reduce the strength by 3%. Fact.

In my opinion though, this is NOT enough to get excited over. As said previously…something else is far more likely to fail than a hard shackle that’s been unscrewed by a quarter turn. There are weaker points in your recovery setup, whether you know it or not. Fact.

Now if you’re someone who got bothered or upset by anything said here, you really need to take a closer look at the welds on your bumpers. Specifically the ones holding the recovery point brackets to the bumper. Those are probably the weakest link in your recovery system. Opinion. Unfortunately welds are all different and have different tolerances (even if done by machine), so we can’t say for sure just how much weaker that recovery point becomes because bumper manufactures don’t do much (if any) destruction testing.

Another point to consider in your rigging is the forward and side load forces that recovery points are subjected to when used as part of a bridle. The math on this gets complicated but YouTuber Robert Pepper has a video on this topic. Not only is he an experienced off-roader, but he’s also an engineer, and he does some extremely detailed, deep-dives into recovery rigging.

There is a tremendous amount to think about in every recovery, and I’ve never had two that were exactly the same. Similar sure, but never exactly the same. So don’t get hung up on details that, in the bigger recovery picture, aren’t that significant.

Previous Post

Previous Post Next Post

Next Post